Introduction

As anyone in the industry knows, the need for greater computational power drives evolutionary changes in processor design. Today we’re seeing an accelerating shift from traditional, monolithic single-die configurations toward more advanced, chiplet-based multi-die processor assemblies, with growth at up to a 86% CAGR depending on the market segment. This shift, though desirable for performance, also offers other advantages, including flexibility, modularity, and cost optimization, so the big silicon suppliers, including Nvidia, Intel, and AMD, have publicly committed to multi-die processor assemblies. They’re clearly the future.

However, there’s a downside to multi-die processors. While multi-die architectures offer remarkable performance gains, they also introduce significant thermal management challenges, in part because the 2.5D and 3D physical designs increase heat density in ways conventional air-cooled technologies can’t easily address. The increasing complexity of multi-die designs, the ways they impede airflow, and heat differentials from die to die, coupled with the accelerated increase in processor thermal design power (TDP) demands are pushing silicon suppliers, server manufacturers, and cloud service providers to explore innovative cooling solutions capable of addressing millimeter-sized localized heat flux and temperature gradients.

In this paper, we’re going to:

- Understand why these processors are difficult to cool

- Explore the market consensus on possible solutions to the cooling challenge

- Dig into the distinctive technologies JetCool brings to the problem

- Examine the real-world experiences our customers have encountered when using our patented SmartLid designs for intensive high-TDP requirements.

The Challenge: Heat and Hot Spots in Multi-Die Assemblies

The core problem in cooling multi-die processors revolves around an intrinsic design issue: inherent non-uniformity in power distribution and resulting localized hotspots. For example, multi-die packages like AMD’s Threadripper series, combine dies of varying power densities within a single package, creating a complex thermal landscape unlike the thermal distribution of a typical single-die processor.

We conducted a study, “Thermal Performance of Modular Microconvective Heat Sinks for Multi-Die Processor Assemblies,” which determined that the integration of multiple dies inherently increases thermal resistance and amplifies localized cooling problems. This added resistance is due to the interfaces between the dies, the interposer (if present), and the package substrate. This increased resistance, coupled with non-uniform power distribution from die to die, leads to significant temperature differentials across the processor surface. These differentials create localized, non-uniform areas of high heat density (thermal gradients) that can result in:

- Limits on total operating power

- Increases in leakage currents

- Mechanical stress due to differential thermal expansion

- Restricted performance

- Reduced processor longevity

These issues, if left unchecked, reduce the overall efficiency of multi-die-based systems and also reduce the long-term operational value of those systems. Failure rates increase due to problems that include cracking and delamination due to excess heat, causing downtime, and downtime reduces ROI.

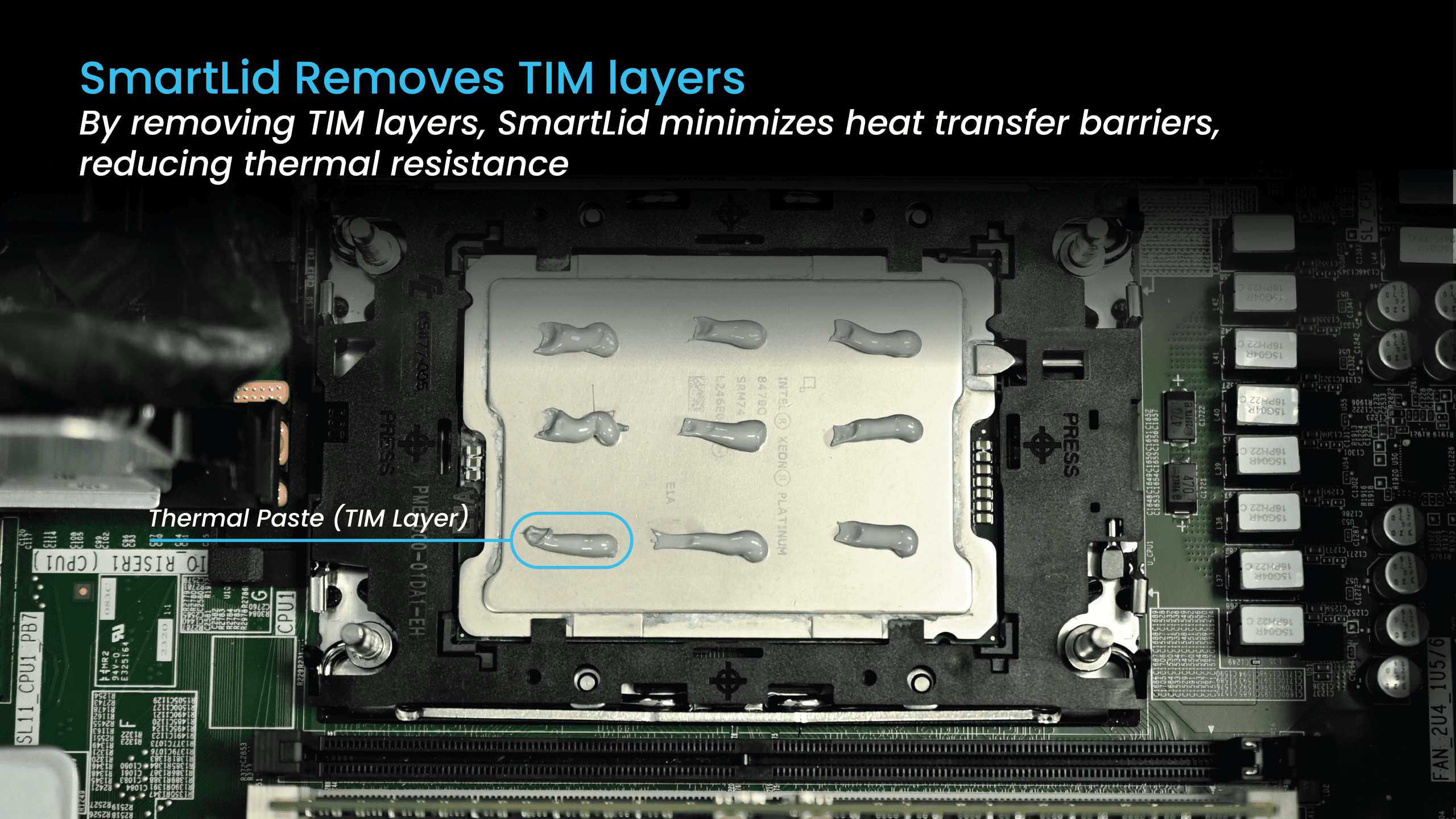

Of course, processor designers aren’t entirely unaware of these problems; silicon manufacturers add design features to improve cooling. The principal feature — thermal interface material (TIM) layers — help address the heat challenge of these processors. While TIM layers play a crucial role in reducing thermal resistance between the die and the heat spreader or cold plate, they often struggle to effectively manage the concentrated heat fluxes generated by individual dies within a multi-die package. This is especially true as TDPs continue to climb, pushing the limits of what conventional TIM layers can handle. The TIM layer, though important, is already insufficient to consistently cool the hottest processors under demanding conditions.

It’s become clear that silicon manufacturers, server manufacturers, and cloud service providers need a better way to ensure processors aren’t damaged or destroyed by heat.

Emerging Cooling: A Shift to Liquid

These challenges lead us to liquid cooling. Since liquids of various types offer higher heat capacities and better thermal conductivity, it’s becoming increasingly clear that liquid cooling is a key enabling technology for high-TDP, multi-die processors that otherwise would bake or fry in their own heat. The CEO of a critical server manufacturer believes that liquid cooling will be installed in 30% of racks by the end of 2025, and a silicon manufacturer says that liquid cooling will be necessary to keep up with TDP increases.

Though it’s clear that data center operators need liquid cooling, it’s clear that different liquid cooling technologies are jockeying for position. The data center market is filled with various liquid cooling technologies, ranging from rear door heat exchangers to immersion cooling, from microchannel cold plates to JetCool’s distinctive solution, microjet direct-to-chip convective cooling®.

Of course, dozens of vendors tout their technologies, making claims that their offering is superior to others. However, many of these claims aren’t backed by research. After years of research and testing, both by JetCool and by third-parties, it’s becoming clear that our microjet direct-to-chip cold plates are proven and mature, eliminating the challenges caused by heat differentials in high-TDP, multi-die processors, and also sidestepping the problems of other approaches to liquid cooling.

The Mechanics of Microjets

What are microjets? Microjets are compact cooling arrays that direct liquid streams perpendicularly onto the die surface. Unlike conventional methods, microjets target localized heat flux areas with high precision, achieving heat transfer coefficients of up to 414,000 W/m²K—a performance level that surpasses traditional microchannel cooling by reducing pressure drops and minimizing temperature gradients.

Key design parameters for microjets include:

- Low Operating Pressure: Microjets operate effectively at 2–5 psi, reducing pump power requirements and enhancing energy efficiency.

- Flow Distribution: Microjets distribute coolant directly to hotspots, eliminating the need for heat spreaders and reducing thermal resistance.

Performance Benefits of Microjets

- Exceptional Thermal Performance: Microjets maintain high heat transfer rates while limiting pressure drops. Increasing jet velocity improves heat transfer performance by 1.6x, providing processors with greater thermal headroom for enhanced power and efficiency — making it easy to cool over 5kW TDP in a single socket.

- Extended Reliability: Microjets exhibit remarkable durability confirming negligible erosion and clogging risks. Even after extended use, they maintain consistent performance, ensuring a long lifespan.

- Graceful Degradation: Unlike traditional cooling methods, microjets degrade gradually over many years. Even after a decade of use, they retain high performance, offering predictable and reliable operation in critical environments like AI-driven data centers.

- Low Pressure and Power Consumption: Operating at pressures as low as 2–5 psi, microjets require minimal pumping power. This efficiency reduces operational costs and aligns with data centers’ sustainability goals.

Reliability and Durability Benefits

Not only do microjets offer superior performance, they also redefine reliability and durability in advanced cooling systems:

- Clogging Prevention: Status quo 50 µm filters ensure sustained performance by preventing clogs and maintaining smooth operation, offering peace of mind for long-term use.

- Erosion Resistance: Rigorous testing under high-velocity fluid impacts confirms their robustness. SEM images taken after thousands of operational hours reveal no detectable surface degradation, affirming their longevity.

The performance, reliability, and durability advantages of microjet convective cooling relieve the challenges faced by multi-die processor manufacturers. And JetCool leads the pack with our microjet design for high-TDP multi-die processors: the SmartLid.

SmartLids: A Game-Changer in Processor Cooling

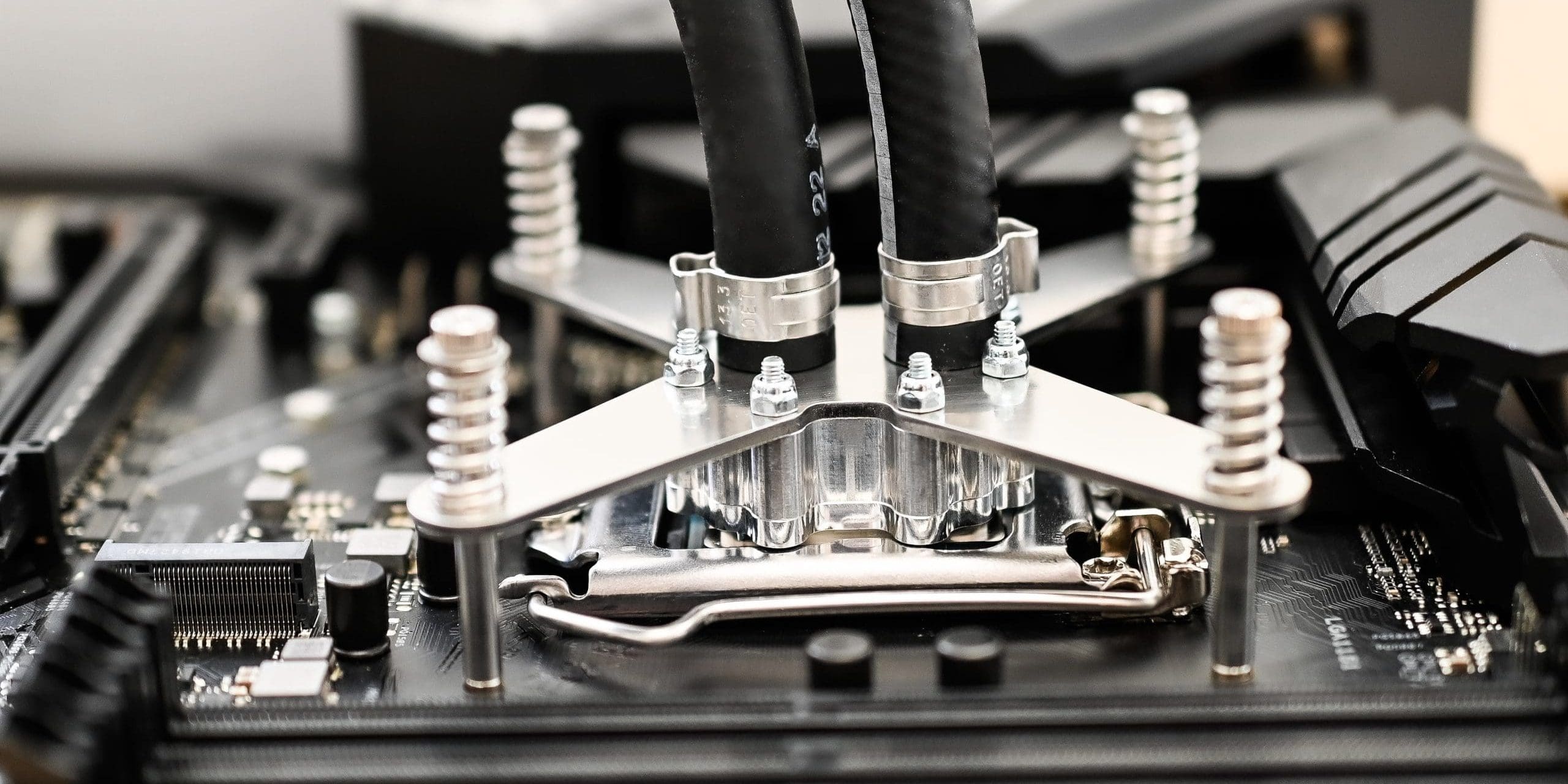

SmartLids, bonded or sealed directly to processor dies, eliminate the inefficient, ineffective TIM layer. SmartLids deliver unparalleled thermal performance, reducing thermal resistance to as low as 0.01 K/W. In the ASME study, JetCool’s SmartLid demonstrated the potential of microconvective cooling, achieving a 75% improvement in power draw performance over nominal TDP during overclocking tests. This breakthrough showcases the transformative power of direct-to-die cooling in pushing processor performance to new heights.

How SmartLids Work

SmartLids leverage microconvective cooling principles, utilizing optimized single-phase impingement cooling to target hot spots on semiconductor dies. By eliminating TIM layers, SmartLids:

- Reduce Thermal Resistance: Direct die-to-cold-plate contact minimizes heat transfer barriers.

- Enhance Processor Efficiency: Lower operating temperatures reduce leakage currents, boosting CPU efficiency by up to 10%, as demonstrated in the ASME study.

- Improve Reliability: Removing TIM layers eliminates risks such as material dry-out and thermal degradation, extending device lifespans.

Pioneering a New Standard in Cooling

As processor architectures transition to high-power, multi-die, and 3D-stacked configurations, the limitations of conventional cooling methods become increasingly evident. Targeted cooling technologies like SmartLids can cool over 2.5kW in a single socket while achieving localized high-power-density heat removal, ensuring processors operate at full utilization without thermal throttling.

JetCool’s SmartLids, currently in production environments today, provide a scalable, implementation-friendly solution for the next generation of processors. By addressing localized heat flux and enabling the removal of TIM layers, SmartLids pave the way for increased computational density and efficiency in data centers.

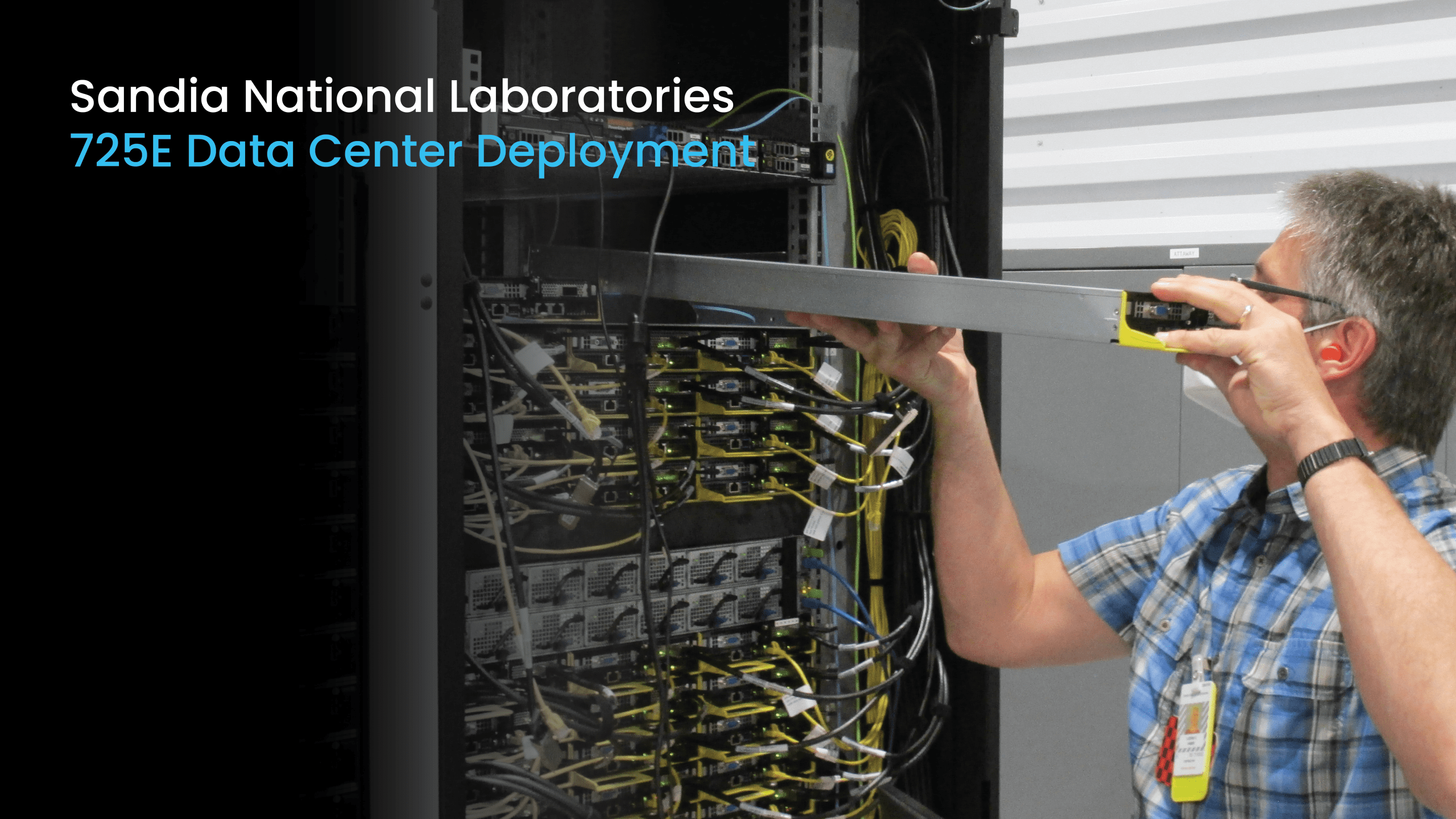

Sandia Special Report: A Sustainable Edge

SmartLids also align with sustainability goals. By enabling the use of warm inlet coolant temperatures—often exceeding 60°C—SmartLids support free cooling and reduce the reliance on water-intensive chiller systems. This is especially critical as data center water consumption has risen by nearly two-thirds over the past five years.

At Sandia National Laboratories’ 725E Data Center, JetCool’s SmartLids cooled a high-performance computing (HPC) cluster. SmartLids maintained thermal efficiency even at coolant temperatures as high as 65°C, ensuring processors operated without throttling. JetCool’s microconvective cooling also enabled significant water savings, reducing usage by up to 90%, a critical advantage for facilities like Sandia that are striving for sustainability.

Explore the full results and learn how JetCool’s solutions are driving efficiency and sustainability in HPC cooling in the Sandia National Lab Special Report.

Conclusion

The rise of multi-die assemblies and high-TDP processors demands innovative cooling solutions. JetCool’s SmartLids, grounded in the principles of microconvective cooling and validated by cutting-edge research, offer a transformative path forward. By eliminating the TIM layer, SmartLids deliver the thermal performance, efficiency, and reliability required for modern processors, setting a new standard in direct-to-die cooling. JetCool’s patented microjets not only enable direct-to-die cooling—eliminating the TIM layer for superior heat transfer—but also offer a scalable, low-pressure solution that combines exceptional thermal performance with long-term reliability.

For organizations looking for the leading single-phase direct-to-chip solution for high-power chipsets, contact JetCool today to discover how SmartLids can transform your high-performance computing infrastructure.