As data centers transition from air cooling to liquid cooling to meet escalating power and cooling demands, Coolant Distribution Units (CDUs) have become essential for managing the substantial thermal loads generated by high-performance servers, especially in AI and HPC environments.

According to Uptime Institute’s recent report, Capacity Planning for Liquid-Cooled Data Centers, a growing number of operators recognize the need to introduce liquid-cooled racks to handle the intense heat produced by advanced silicon that air cooling alone can no longer manage.

The heat of servers is mostly generated by the processors (e.g., CPU, GPU). For traditional servers, the heat is mainly from CPUs, which have a typical Thermal Design Power (TDP) of 250-350 watts per CPU.

However, for AI servers based on GPUs or custom AI accelerators, one GPU (e.g., Nvidia GB200) has a TDP of 1.2kW watts today, and a typical GB200 NVL72 server with 8 GPUs and 2 CPUs, has a total TDP of 10,000 watts per AI server, as compared to 700 watts for traditional servers with two CPUs.

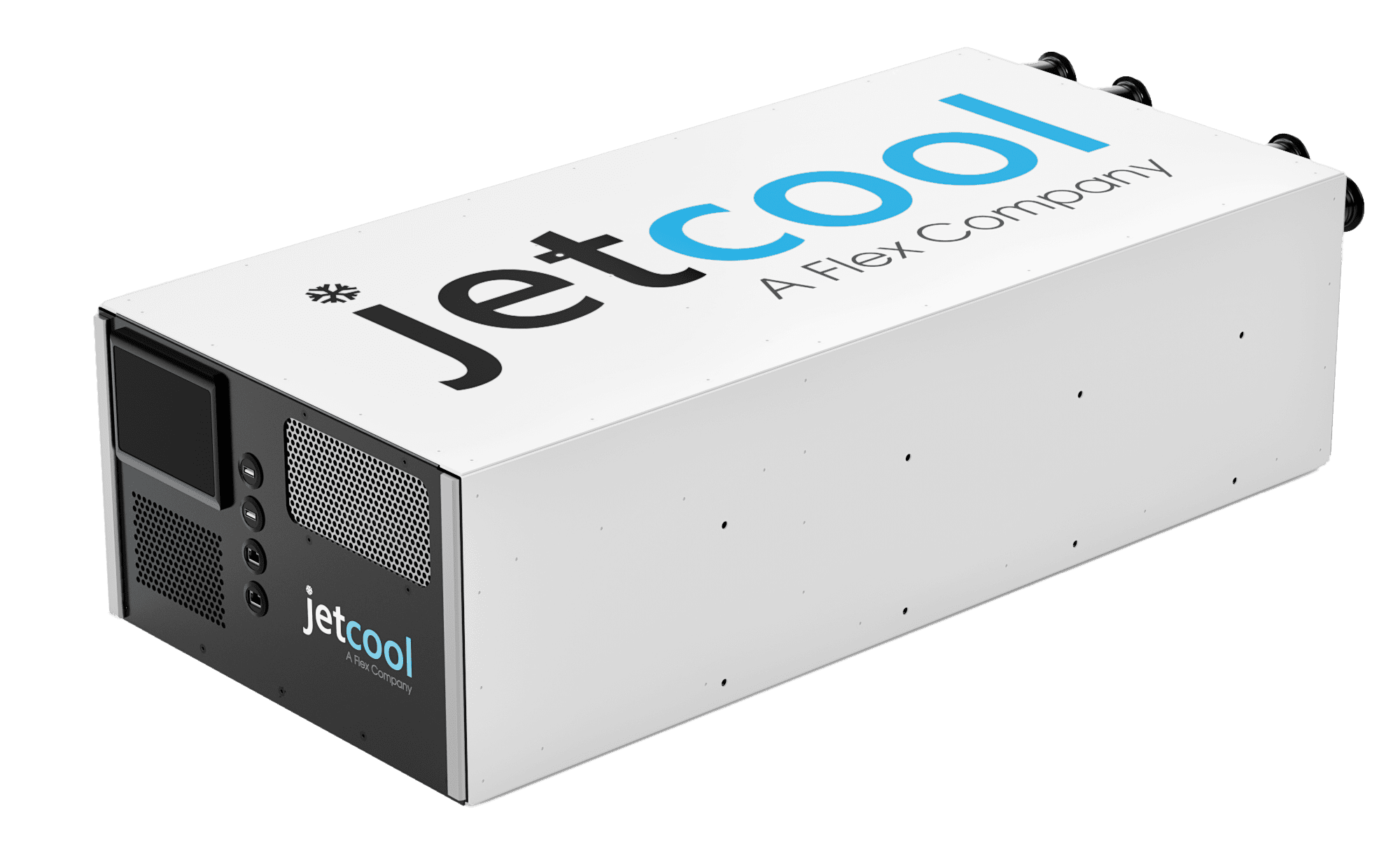

JetCool’s new SmartSense CDU addresses these needs with a scalable, high-capacity cooling solution designed for power-intensive data centers. In this guide, we explore the fundamentals of CDUs and highlight how JetCool’s SmartSense CDU can help operators manage their cooling requirements effectively.

What is a Coolant Distribution Unit (CDU)?

A CDU is a specialized device within a closed-loop liquid cooling system that precisely manages coolant temperature and flow rates, ensuring optimal cooling efficiency. By controlling the flow of coolant to IT equipment and returning it to the facility’s water for re-cooling, CDUs stabilize temperatures and reduce the risk of overheating.

The CDU’s role in direct liquid cooling (DLC) is critical, as it allows for temperature conditioning to prevent condensation and isolates the IT equipment from the facility water, which may be harsher due to higher levels of particulates, minerals, and potential chemical treatments that can corrode or clog sensitive IT cooling components

Components of a Liquid-to-Liquid CDU

A Liquid-to-Liquid CDU is a type of CDU that transfers heat from the IT equipment’s coolant loop to the facility’s water loop. This setup is commonly used in high-density environments where facility water is available. Key components include:

- Heat Exchanger: Transfers heat from the secondary IT equipment coolant loop to the primary facility water loop, determining the CDU’s cooling capacity.

- Primary and Secondary Pumps: Circulate coolant in both loops; secondary pumps push coolant through the IT equipment, while primary pumps circulate facility water through the heat exchanger. JetCool’s SmartSense CDU includes redundant pumps with automatic switching for uninterrupted operation. While all CDUs will have secondary pumps, not all CDUs will have primary pumps – this depends on the facility.

- Temperature Control System: Maintains coolant at the desired temperature, preventing condensation by adjusting the coolant temperature to stay above the dew point.

- Flow Control Mechanism: Delivers the correct amount of coolant to IT equipment based on heat load requirements, with adjustable valves and flow meters to monitor flow.

- Filtration System: Cross-connected filtration in advanced CDUs, such as the SmartSense CDU, keeps coolant free from contaminants, enhancing efficiency and extending component lifespan.

- Sensors and Leak Detection: Monitor parameters like temperature, pressure, and flow rates, and detect leaks to enhance safety.

- Control Unit: Acts as the CDU’s central processor, collecting data, managing pumps, regulating temperature, and interfacing with the facility’s management system for remote monitoring and troubleshooting.

Components of a Liquid-to-Air CDU

A Liquid-to-Air CDU uses air-cooled radiators to dissipate heat from the IT equipment’s coolant loop into the surrounding air, eliminating the need for facility water. This type of CDU is typically deployed in scenarios where facility water is unavailable. Key components include:

- Air-Cooled Radiator: Dissipates heat from the coolant to the surrounding air, largely determining the CDU’s cooling capacity.

- Fan System: Facilitates air movement over the radiator to enhance heat transfer from the coolant, with designs optimized for energy efficiency, noise reduction, or performance.

- Pump: Circulates coolant through the IT equipment and radiator, ensuring continuous flow and supporting specific pressure and volume requirements.

- Temperature and Flow Control: Maintains optimal coolant temperature and flow rate based on IT equipment heat load.

- Filtration System: Keeps the coolant free of particles that could obstruct the radiator or other components.

- Leak Detection: Identifies leaks in the coolant loop, protecting IT equipment and maintaining system integrity.

- Control Interface: The CDU’s central command unit, which collects data from sensors, adjusts cooling parameters, and enables remote monitoring for reliable performance under varying thermal loads.

Comparing Liquid-to-Liquid vs Liquid-to-Air CDUs

Both Liquid-to-Liquid and Liquid-to-Air CDUs serve the essential function of cooling IT equipment, but they have different applications.

Liquid-to-Liquid CDUs are ideal for facilities with facility water access, making them common in high-density environments due to their efficient heat transfer.

Liquid-to-Air CDUs, on the other hand, are suited for data centers without facility water, offering flexibility but with a lower overall cooling capacity and lower efficiency benefits.

Both types of CDUs require regular maintenance to ensure optimal performance. Maintenance tasks include inspecting pumps and filters, checking for leaks, and conducting performance testing. To minimize downtime, operators should ensure redundancy in cooling infrastructure, implement leak detection systems, and use quick disconnect in-rack manifolds for faster, safer maintenance.

While JetCool has plans for Liquid-to-Air CDUs in the future, this guide focuses on the benefits of Liquid-to-Liquid CDUs.

JetCool’s SmartSense CDU: Scalable, High-Capacity Cooling for Power-Dense Racks

The JetCool SmartSense CDU is a high-performance, rack-mounted liquid-to-liquid 6U CDU built to handle the intense thermal loads of GPU-dense, high-power racks. With a cooling capacity of up to 300kW per rack, or neighboring racks, and scalability to row-based configurations delivering 2MW+ cooling capacity, the SmartSense CDU ensures efficient, reliable cooling for data centers. Paired with JetCool’s advanced cold plates, the SmartSense CDU provides a complete, end-to-end solution for even the most compute-intensive environments.

Key Features of JetCool’s SmartSense CDU

- Ultra-Efficient, Redundant Pumps: Quiet, reliable pumps with automatic switching for continuous operation.

- Support for Warm Inlet Temperatures: Allows for inlet temperatures up to 60°C, maximizing GPU utilization and enhancing performance.

- Cross-Connected Filtration: Delivers ultra-clean fluid distribution for enhanced efficiency and IT protection.

- Flexible Rack Compatibility: Designed for 42-inch+ (1070 mm) deep racks in 19-inch and ORV3 form factors, ensuring compatibility with diverse configurations.

Ensuring Reliability: Maintenance, Redundancy, and Safety Measures

To maintain optimal performance and minimize the risk of system failures, data center operators should follow regular maintenance protocols for CDUs and other liquid cooling infrastructure. Key considerations include:

- Scheduled Maintenance: Regularly check coolant levels, pump functionality, and filtration systems to prevent system failures.

- Redundancy in Cooling Infrastructure: Build redundancy to avoid downtime during maintenance. The SmartSense CDU’s redundant pumps ensure continuous operation even in case of pump failure.

- Leak Detection Systems: Early detection and prompt response to leaks can prevent costly damages.

- Quick Disconnect In-Rack Manifolds: Allow for rapid servicing and reduce leak risk, simplifying maintenance tasks.

- Performance Testing: Routine testing validates energy savings, verifies system security, and ensures cooling performance meets high-density, high-power demands.

Selecting the Right CDU for Data Center Needs

Selecting an optimal CDU requires understanding specific thermal management needs. Key factors include:

- Heat Load: Dictates flow rate and cooling capacity, based on the thermal design power (TDP) of IT components.

- Desired Approach Temperature: The targeted temperature difference between facility water and the coolant exiting the CDU.

- Cold Plate Flow Rate: Required coolant flow to meet maximum case temperature (Tcase) targets for processors.

For example, if a facility supplies water at 20°C and the goal is to maintain a 30°C outlet temperature from the CDU, this 10°C approach temperature will impact the CDU’s cooling capacity requirements. As processors generate more heat, flow rates need to increase to meet the demanding cooling requirements for high power GPUs, CPUs, and custom AI accelerators.

JetCool and Flex: Driving Innovation and Scalability

As a Flex company, JetCool is leveraging Flex’s global manufacturing expertise to scale production of its SmartSense CDU, ensuring a reliable and efficient supply chain for operators transitioning to liquid cooling.

By combining JetCool’s patented microconvective cooling technology with Flex’s proven capabilities, the SmartSense CDU delivers unmatched efficiency and dependability across diverse data center applications. Together, Flex and JetCool are advancing the future of thermal management in high-performance computing.

Future-Proofing Data Centers with the JetCool SmartSense CDU

The JetCool SmartSense CDU is a comprehensive cooling solution that enables data centers to keep up with rising thermal demands while minimizing energy use. Supporting higher inlet temperatures and offering scalable cooling options, the SmartSense CDU meets current and future requirements for AI and HPC environments.

As data centers focus on sustainability and efficiency, JetCool’s SmartSense CDU, combined with Flex’s scalable manufacturing, offers an innovative, reliable cooling solution prepared for next-generation workloads. To find the right CDU for your data center needs, contact the JetCool team.