As artificial intelligence (AI) and high-performance computing (HPC) workloads continue to expand in scale and intensity, cooling infrastructure has become a key design consideration. Facilities that were once optimized for general-purpose IT now face thermal loads that can exceed 30 kW per rack, and in hyperscale deployments, power densities can surpass 100 kW. Consequently, traditional air cooling is no longer sufficient on its own.

Direct liquid cooling (DLC) and hybrid cooling systems are becoming standard in AI environments, with coolant distribution units (CDUs) serving as a vital link between facility water systems and IT hardware. However, not all CDUs are created equal. To develop a scalable, energy-efficient cooling strategy, it is essential to understand the various types of CDUs, their architectures, and which ones are best suited for your environment.

Industry Insight

Purpose-built solutions like JetCool’s SmartSense CDU are designed to address these challenges. By optimizing cooling efficiency for high-density environments and simplifying long-term operations, data centers can streamline their operations, minimize energy consumption, and better prepare for the future.

According to the ASHRAE TC 9.9 Technical Alert, the isolation of the Technology Cooling System (TCS) from the Facility Water System (FWS) is essential for effective liquid cooling implementation. CDUs are central to this architecture, enabling thermal isolation, improving control and ownership, preventing condensation, and ensuring precise management of coolant temperature, flow, and quality. The ASHRAE report emphasizes that connecting a single Information Technology Equipment (ITE) platform to each CDU optimizes operating conditions and simplifies maintenance. Isolation enables data center operators to minimize risks and enhance the overall performance of their cooling systems while addressing the unique needs of each application.

Understanding W-Class and S-Class Temperature Categories

ASHRAE’s latest guidance introduces complementary temperature classifications for facility water (W-class) and technology cooling systems (S-class). These categories are linked by the CDU’s approach temperature. For example, if your facility water is W35 (35°C) and your CDU has a 5°C approach, your TCS output would be S40, ideal for many high-performance cold plate applications. Designing with this in mind helps operators better align infrastructure targets with hardware requirements, especially as AI deployments push for warmer water cooling and improved energy efficiency.

To better understand how CDUs can meet the specific needs of varying environments, it’s important to explore the different types of CDUs available, each designed with unique capabilities to optimize cooling performance.

The Role of Capital Expenditure (CapEx)

In the context of rising rack densities and the accelerating shift to liquid cooling, managing capital expenditure is more important than ever. The ASHRAE report cautions that deploying oversized CDUs to handle peak loads can introduce unproven risks and lead to substantial upfront costs.

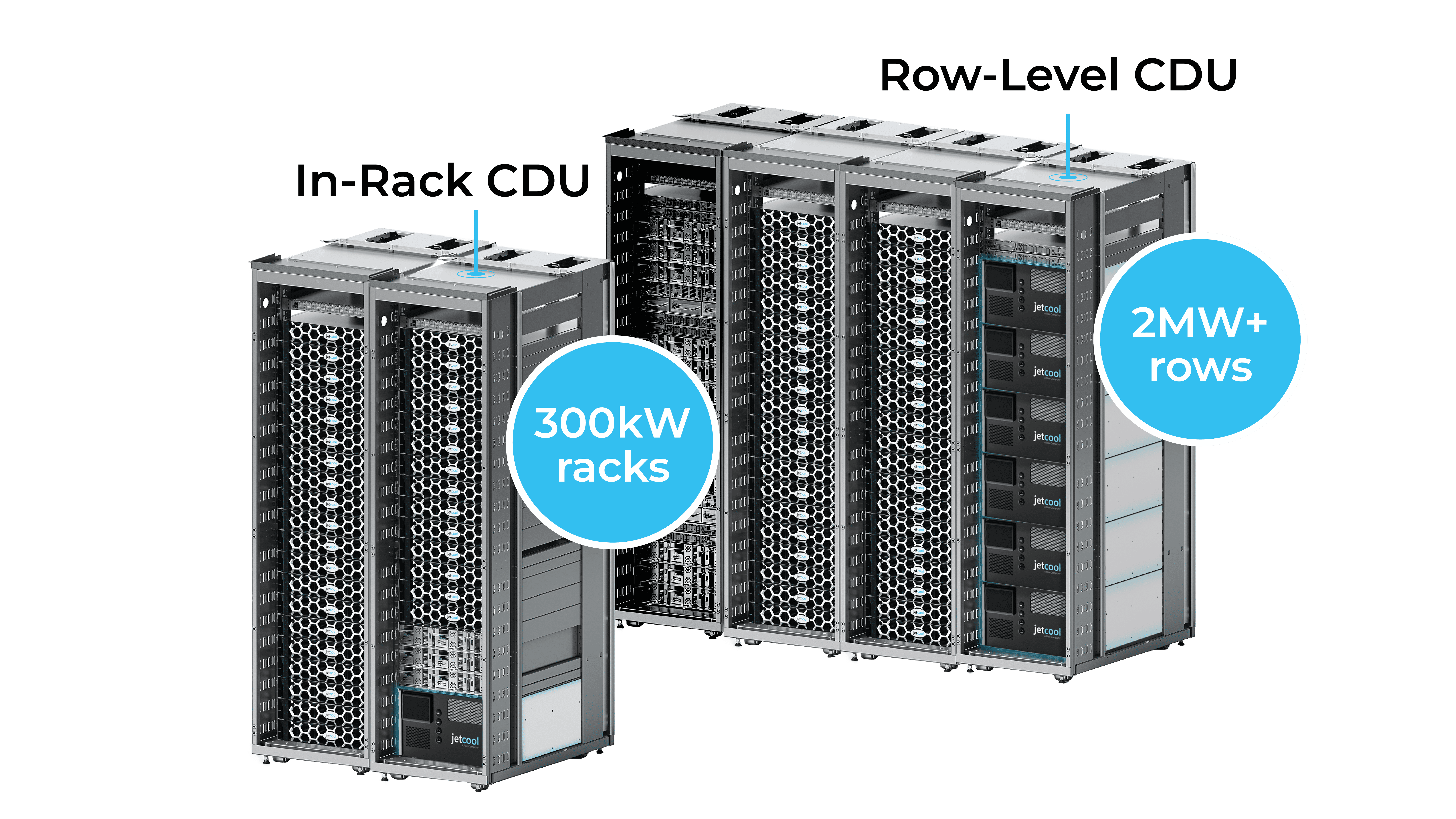

JetCool addresses this challenge with a portfolio of modular CDUs—including its 6U 300kW SmartSense CDU and more modular CDUs on the roadmap. These solutions are engineered for scalability, allowing operators to align cooling capacity with actual demand rather than overbuilding from day one. This modular approach optimizes CapEx by enabling incremental deployment as AI-driven workloads grow, avoiding large investments during initial construction. As next-gen GPUs and CPUs continue to increase rack power densities, JetCool ensures data centers can scale cooling efficiently—without compromising performance or budget.

Types of CDUs: A Quick Comparison

In-Rack CDUs

Definition: In-rack CDUs are mounted within the IT rack, typically at the bottom, top, or side of the rack enclosure.

Use Case: Ideal for ultra-high-density environments with limited floor space, where localized cooling is essential.

Benefits:

- Minimizes coolant travel distance to IT components.

- Enables precise thermal management at the rack level.

- Allows for modular, rack-by-rack deployment.

Row-level CDUs

Use Case: Suitable for edge data centers or mid-sized deployments where rack densities vary but localized control is still desired.

Benefits:

- Centralized cooling for multiple racks in the same row.

- Easier access for service compared to in-rack units.

- Reduces the need for complex facility plumbing changes.

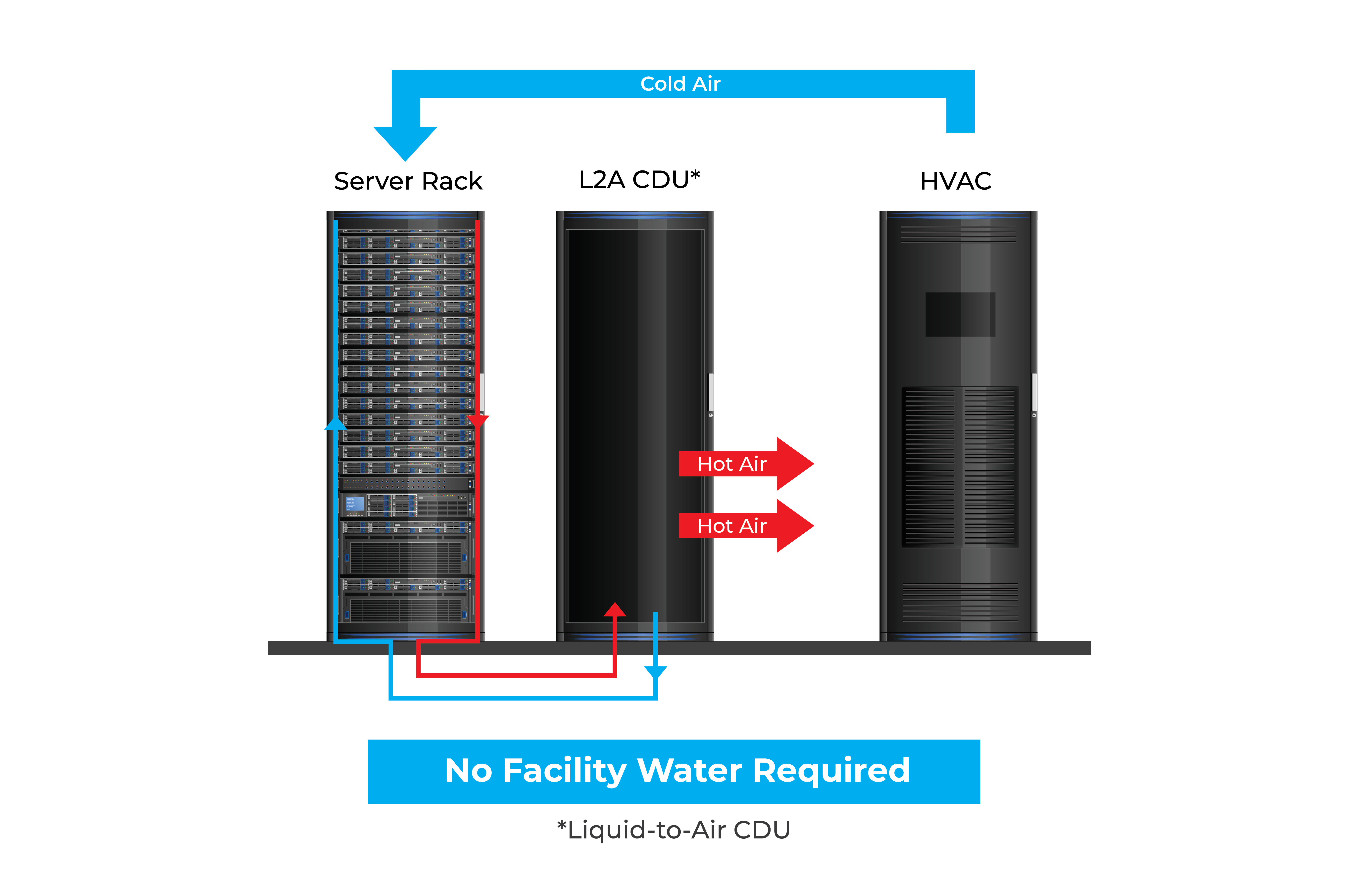

Liquid-to-Air CDUs

Use Case: Useful in facilities without access to chilled water, or as a temporary cooling solution during infrastructure upgrades.

Benefits:

- Eliminates the necessity for building-wide liquid cooling infrastructure.

- Portable and deployable in remote or modular data centers.

- Simplifies deployment in retrofit scenarios.

Liquid-to-Liquid CDUs

Use Case: Common in large-scale data centers with existing chilled water infrastructure.

Benefits:

- Decouples the facility water loop from sensitive IT hardware.

- Supports integration with variable-flow chilled water systems, optimizing energy efficiency.

- Reduces complexities and inefficiencies often found in hybrid air-liquid cooling infrastructures.

- Cools the highest density racks.

CDU Type | Use Case | Cooling Capacity | Facility Water | Placement |

In-Rack Liquid-to-Air | Ultra-high-density racks with no facility water lines | Up to 100kW | No | In-Rack |

In-Rack Liquid-to-Liquid | Ultra-high-density racks with no facility water lines | Up to 300kW | Yes | In-Rack |

Row-Level Liquid-to-Air | Edge data centers for mid-sized setups | Up to 300kW | No | Row-Level |

Row-Level Liquid-to-Liquid | AI data centers, hyperscale environments | Up to 2.1MW | Yes | Row-Level |

Designing for Flexibility vs. Efficiency: The Hidden Tradeoff

JetCool and Flex provide a smarter solution: CDUs and cold plates specifically designed for liquid-first environments.

This enables:

- Warm water-cooling compatibility (up to 60°C inlet / 70°C return) to reduce chiller load and increase energy efficiency.

- Right-sized deployments that avoid low delta-T and over-pumping.

- Simplified scalability with modular, N+1 CDU configurations.

- Faster time-to-market without overbuilding hybrid infrastructure.

The JetCool and Flex Advantage

JetCool’s SmartSense CDU is designed to support high-power liquid cooling deployments with minimal complexity. As part of Flex—a global leader in electronics manufacturing, power systems, and data center solutions – JetCool delivers fully integrated solutions that combine precision cooling and high-efficiency power delivery at the rack level.

Together, JetCool and Flex enable:

-

Complete rack-level systems featuring CDUs, cold plates, manifolds, and quick disconnects—all optimized to work together.

-

Fully integrated power and cooling solutions that accelerate deployment and simplify operations.

-

Global supply chain reliability for large-scale rollouts.

-

Engineering services to support rapid prototyping and custom integration.

Whether you’re deploying rack- or row-level NVIDIA GB200 clusters or building next-gen AI training infrastructure, JetCool and Flex provide the building blocks for scalable, energy-efficient systems—ready for the future of compute.