As AI workloads accelerate compute density and power consumption, traditional cooling methods are no longer enough. At AI Infra Summit 2025, JetCool—a Flex company and leader in direct-to-chip liquid cooling—is showcasing how precision-engineered, end-to-end liquid cooling solutions are redefining performance, efficiency, and scalability in AI data centers.

Flex + JetCool: Your One-Stop Data Center Partner

As part of Flex, we tightly integrate power, cooling and infrastructure with global operations to design, build, and deliver end-to-end liquid cooling solutions—all in-house. From hybrid cooling systems and precision cold plates to coolant distribution units, in-rack manifolds, and quick disconnect couplings, our portfolio supports customers at every stage of their liquid cooling journey. These solutions leverage JetCool’s patented microconvective cooling technology, which targets processor hotspots directly delivering precision cooling—even under the most demanding workloads.

Together, Flex and JetCool offer more than just technology—we’re a long-term partner supporting the entire data center value chain, enabling scalable, high-performance infrastructure anywhere in the world.

Products on Display at AI Infra Summit 2025

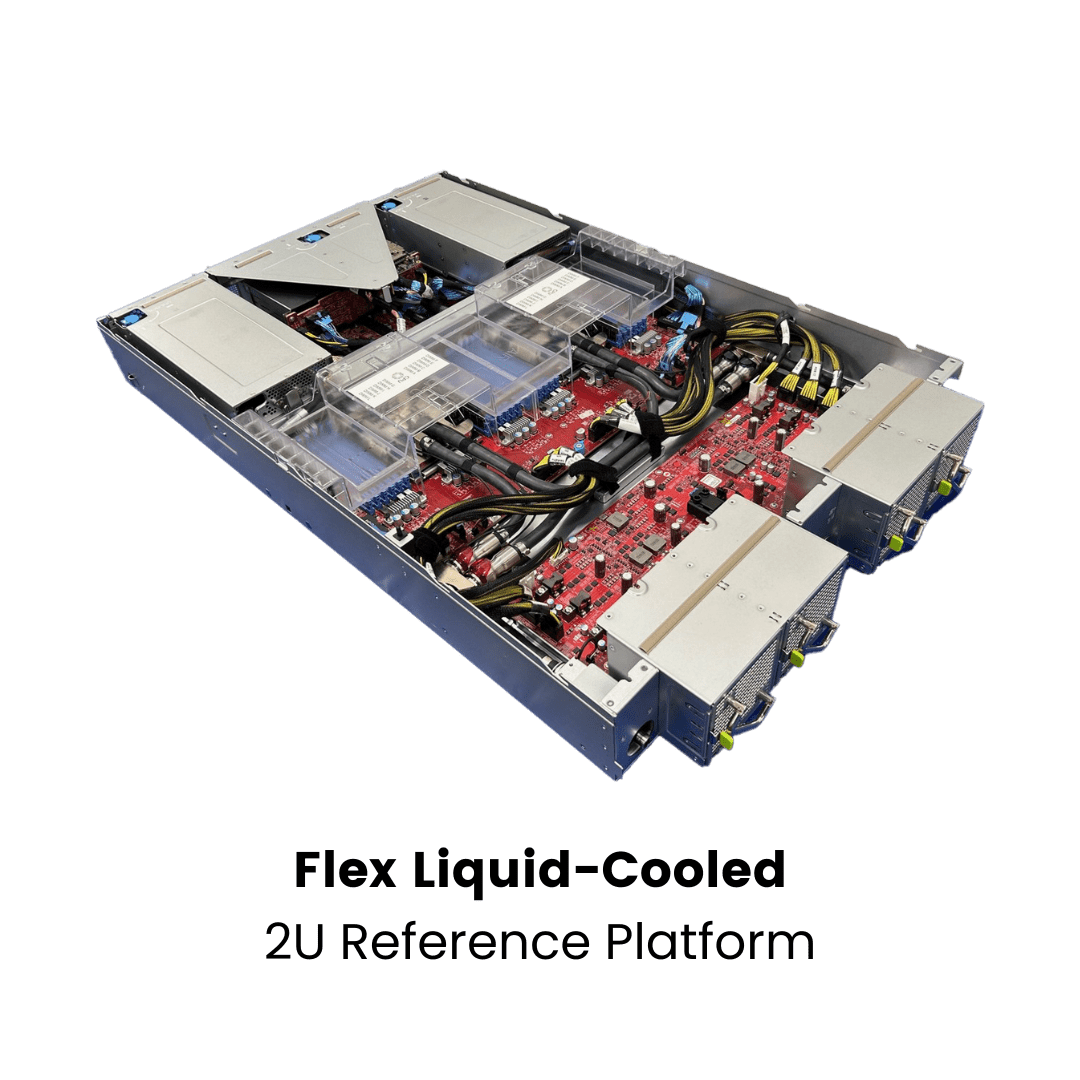

Flex Liquid-Cooled 2U Server with JetCool’s SmartPlate ™ Technology

Precision Cold Plates with Microconvective Cooling®

SmartSense Coolant Distribution Unit

The JetCool Advantage

- Performance: Lower die temperatures let hardware run at higher sustained power without thermal throttling.

- Efficiency: Warm-water, high-ΔT operation reduces chiller dependency and improves data-center energy metrics.

- Scalability: Modular CDUs and factory-integrated rack builds let you replicate validated designs across sites without costly field rework.