Innovate High-Power Devices with Semiconductor Liquid Cooling

Manufacture high-performance devices with enhanced power density and improved device efficiency ahead of your competition with JetCool’s liquid-to-chip (or direct-water) cooling. We’ve developed several microconvective cooling® approaches that can be integrated at various levels of the semiconductor device, depending on the application and desired level of cooling. Our silicon cooling integration approaches include SmartLid™ (fluid-to-die) and SmartSilicon™ (embedded in silicon substrate).

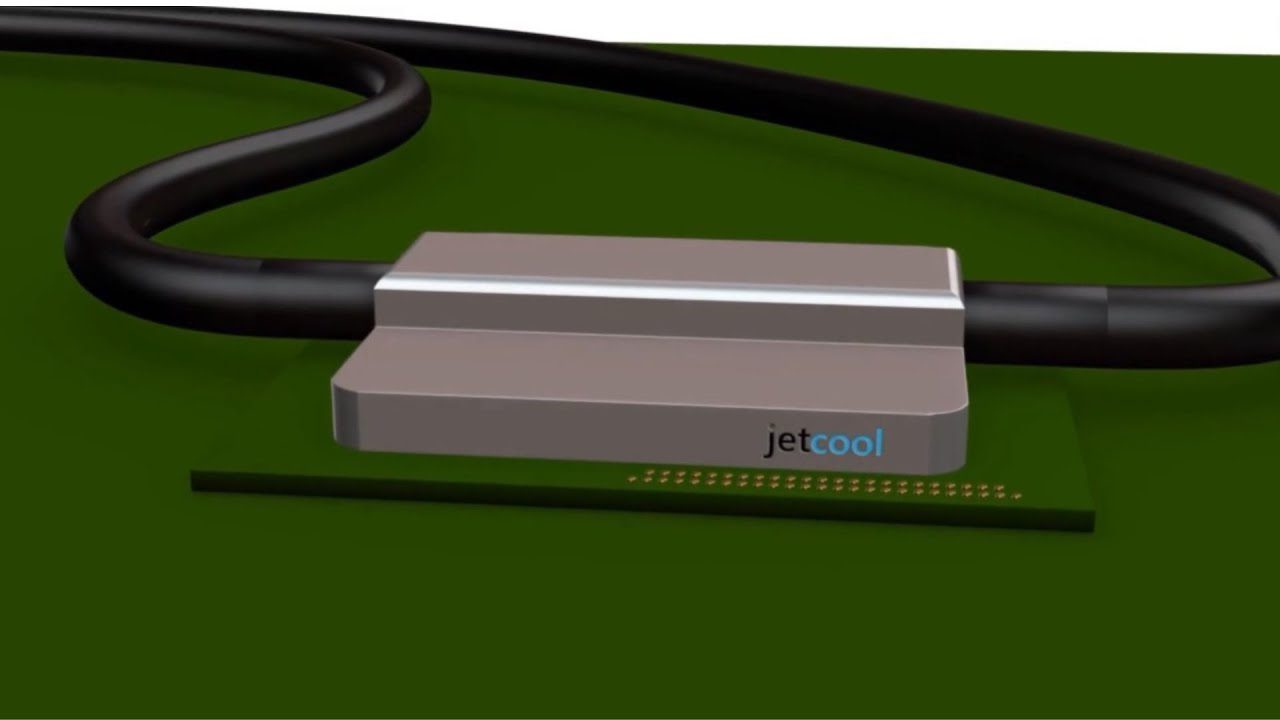

SmartLid Solution

Target Chip Hot Spots Directly with Liquid-to-Die Cooling

Support greater CPU and GPU densities with our SmartLid solution. SmartLid brings the benefits of our patented microconvective liquid cooling technology to semiconductors utilizing microjets to pass liquid coolant directly to the chip’s surface, targeting hot spots to increase device performance and lifetime. Delivering the most effective cooling for today’s CPUs, GPUs, and ASICs, SmartLids enable engineers to:

- Achieve 18% energy savings by raising coolant temperatures over 60°C

- Optimize OPEX by balancing free cooling with evaporative cooling in any climate

- Future-proof system design with the capacity to cool the next three generations of processors, including those that exceed 1,000W per chip

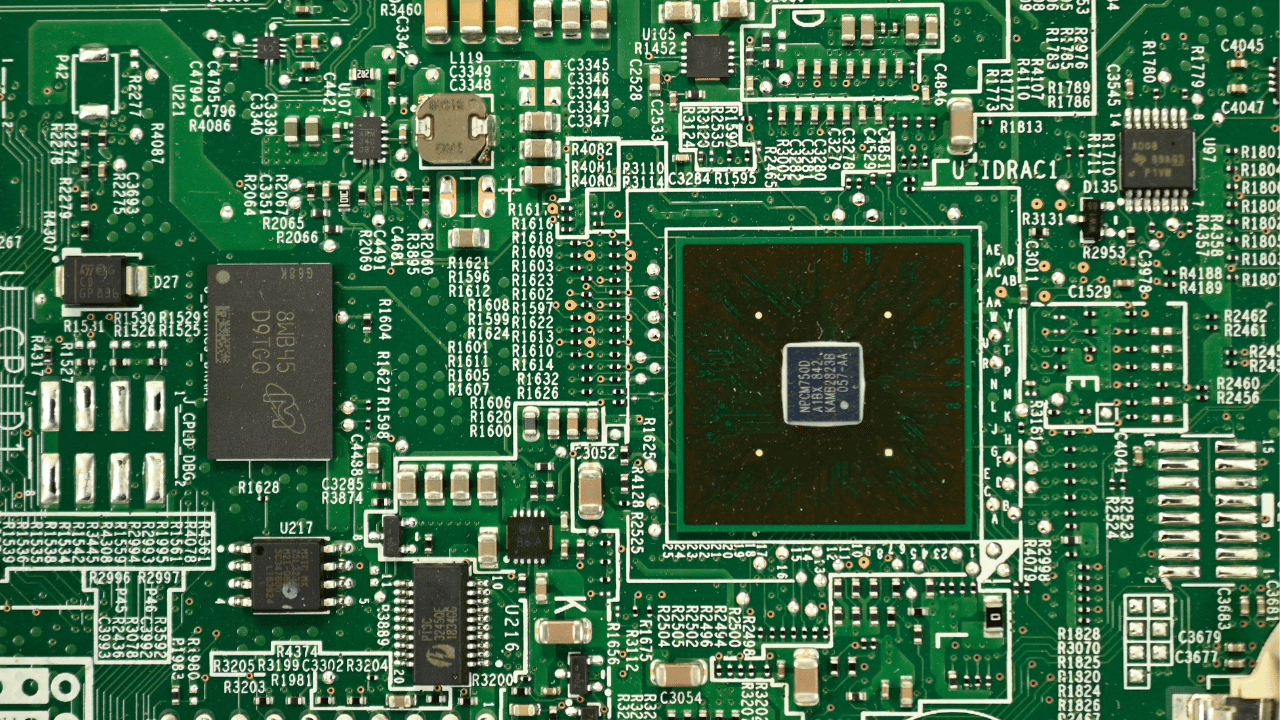

SmartSilicon

Mitigate High Heat Fluxes and Integrate Multi-Die Stacking Architecture

Our on-chip, semiconductor-integrated liquid cooling provides significant system performance and power efficiency advantages in the smallest size possible for high-power density devices. Our on-chip cooling solution embeds directly into the chip substrate to circulate coolant and target the die’s hotspots, increasing control over chip temperatures. With embedded silicon liquid cooling, engineers can:

- Deploy ultra-high TDP cooling (>1,000W), removing thermal constraints

- Reduce operating temperature, increasing device efficiency

- Eliminate thermal pastes, minimizing thermal resistance